Visit my other sites!

ChevelleCD - Chevelle CDs & Books

Chevelle/Camaro/Nova/HHR/SSR Registries

Webs By Dale - Web Site Development

| [ Back ] Alternator This presented its own set of problems. Remember all the fabricated brackets and the custom made bar-stock threaded into the passenger side head? The supplied forward mounting bracket and the slick turnbuckle adjuster work just fine bolting to the water pump. The bolt that goes through the alternator into the head for support was the problem. The bolt has a 3/8" thread, my head was tapped for the 7/16" custom threaded bar-stock. Naturally it wouldn't fit.

Note the new bracket also uses Allen head bolts (all supplied bolts are Allen head by the way) and the bolt heads are recessed in the brackets for a clean look. First, the new 1-wire alternator I bought will fit the 3/8" bolt supplied but not the custom bar-stock (7/16") I had made. (I must have drilled out the old alternator some time back.) So, it's back to the machine shop to have a new lower bar/bolt made; this time with a 3/8" diameter rod cut in front of the hex, threading it for a 3/8" nut, and an additional 1/2" to extend through the hole and secure with a nut. Not as clean as the supplied bolt, but it beats drilling out the head and installing a 3/8" Heli-coil and taking a chance of screwing it up good. Oh yes, the kit supplied pulley/fan for the alternator fit perfectly. Whoopee! I also test fit the water pump pulley and guess what? There appears to be a small ridge in front of the mounting surface that won't allow the pulley to snug up. It's either (1) grind down this ridge on the water pump shaft, (2) ream out the hole on the pulley, (3) or use washers behind the pulley to space it away from the mounting surface. End of Day One - Phew! Day Two - April 20, 2001 My wife picked up a bag of 3/8" washers of various sizes while I was at work - bless her heart. Too tired to work on it tonight and besides, the weekend is coming right? I did take the old 7/16" bar stock to the machine shop along with the kit supplied 3/8" bolt to have a new one made. Won't be ready until Monday or Tuesday. That's alright, this weekend will be devoted to the power steering pump. Stopped at Auto Zone and picked up some necessities; high heat black for the radiator, a new power steering cap (didn't come with one), and a power steering belt. The belts are suggested in the kit but are not supplied. Naturally Auto Zone only had the power steering size (5-rib and 37") but not one for the alternator (suggested as a 6-rib, 42." unit). Won't be ready for the alternator till next week anyway. Day Three - April 21, 2001

All seemed to be going very well today. I had to play around with the p/s pump and washers to get alignment right - this seems to be an area of concern with everyone I've talked to with these kits. Buy a bag of 20 or so 3/8" flat washers and deal with it. On the adjustment bracket there are two washers just visible on the top bolt. The rear bracket also has 2 washers to move the pump forward. The adjustment bracket/pump adjusting bolt has one washer on the outside of the bracket and two more on the inside of the bracket between it and the pump itself. It's very tight getting to the adjustment bolt behind the pulley!

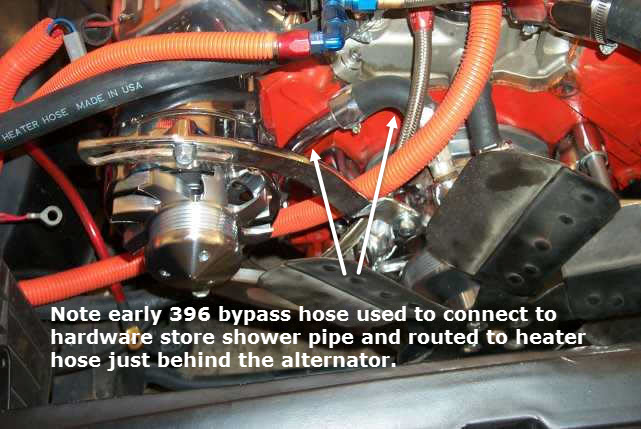

Hoses I don't think are going to be as big a problem as I had first suspected. The return line is a no-brainer and the pressure line from the old two piece pump/reservoir will even fit with a bit of twisting of the rubber hose. Going shopping tomorrow for a new pressure hose and see if I can get a bit of a different model to fit better. Here comes the MAJOR problem for my installation. Remember the motor is a 1969 and has the long water pump so fan-to-radiator clearance was an issue. I had a 17" 6-bladed flex fan, no spacer, and a fan shroud - all worked great.

As you can see, the flex fan isn't going to work due to the pitch and the blade size. With the wider ribbed belt setup and the alternator pulled in towards the center of the engine a bit more - well, it won't work. Fan has to come forward at least 1".

With the radiator in place, there is barely 2.25" of clearance between the water pump pulley mounting surface and the radiator. I'm considering the following options: 1. Dual electric fans. Those advertised are for engines up to 250hp and are two inches too wide (that can be remedied I think) and 2.25" deep. The question on the depth is, is that 2.25" at the fan motors or across the entire surface? If it narrows down where the water pump snout is, no problem. My radiator is 25" wide and 16" tall - dual 12" fans are 27" wide by 15.5" tall by 2.25" deep. 2. Fan clutch. Again depth is the problem - just how thick are fan clutches? 3. A fan spacer. Electric fans would look cool - a fan clutch would probably more efficient - a spacer would be the cheap way out although it's toss up between fan/alternator clearance and fan/radiator clearance and finding a 1" spacer. Well, off tomorrow for more shopping and measuring! Day Four - April 22, 2001 Spent the day watching the Talladega race and looking over specs on Spal electric fans trying to figure one, two, or even three that would fit in the limited space. Went back out to the garage to measure some more when it hit me. The problem is the fan hits the alternator. What if I move the alternator back to its original (as it was anyway) location using the original adjustment bracket and discard the turnbuckle unit?

Comparing the two photos above and below, the old alternator brace solution was the simplest. If the alternator is in the way...move it. Duh! It does mean using a longer alternator belt but since Auto Zone didn't have a 42.5" belt anyway, I don't have to take one back. Now if someone makes a belt in the range of 48", I'm home free.

Since the flex fan does have some curvature to the blades, it is still going to interfere with the wider pulleys - both crank and water pump. This can be solved with a simple 1" fan spacer. Before, the fan sat half way in the fan shroud and will now sit 1" closer to the radiator and I'll only have 1" to get the bolts out, but I don't think this will affect the cooling any. If it does, a simple, small pusher fan should suffice in traffic. Only problem might be clearance, 1" fan-to-radiator, when it becomes necessary to remove fan. The radiator may have to come out.

What a difference a little sleep makes! Every problem so far has been overcome by looking at it the next day in a different light. Day Five - April 23, 2001 Took the day off waiting for the lower alternator bolt to be made.

|